|

PALSONITE

|

|

|

iLOWER TEMPERATURE SALT BATH NITROCARBURIZINGj

|

|

|

INTRODUCTION

|

Performance Advantages

|

|

Requirements for high performance of mechanical

|

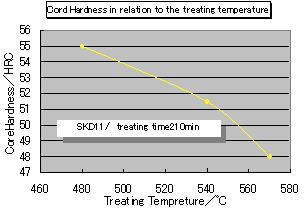

EFerritic Nitrocarburizing while maintaining core |

|

parts have become more stringent with the demands

|

hardness |

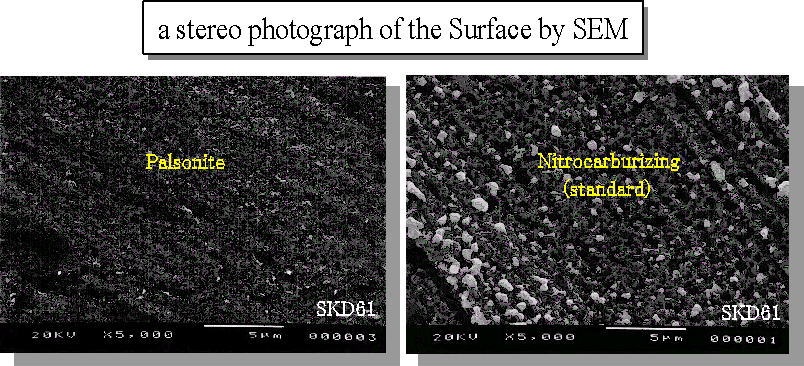

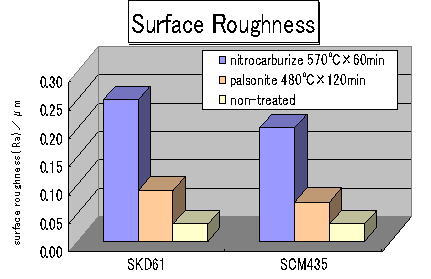

| of todayfs engineered material. One of the most | ELower surface roughness (Ra=0.05-0.1Êm) |

| important requirements is to minimize dimensional | ELess porosity in the compound layer |

| changes and distortion. Palsonite treatment has been | EMinimal dimensional changes |

| invented and developed as a new surface | @@(ex. minimal distortion on sintered metal) |

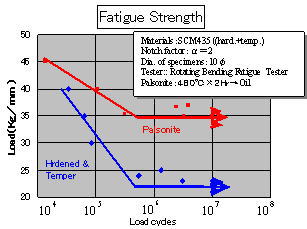

| modification technology to meet these needs . | EImproved Bending Strength in a thin steel plate |

| Palsonite treatment is a lower temperature(430-490j | EGreater Resistance to Wear and Fatigue |

| molten salt technology and is applied to not | EMinimizes the reduction of corrosion |

| only normal carbon steels but also in particular high | resistance in@austenitic stainless steel@ |

| alloy steels. | |

|

|

|

|

|

|

|

|

|

PARKER@NETSUSHORI KOGYO KK

|

|